Access to planning-relevant information - anytime & anywhere

How a web-based solution developed by Intelliact significantly influences project planning processes - from rough to detailed planning

- Swiss family business since 1891

- About 140 employees

- Specialized in gymnasium equipment, sports equipment construction and the installation of equipment in gymnasiums

- Online shop with over 2 000 items of sports equipment

Transparent, up-to-date and reliable detailed planning data

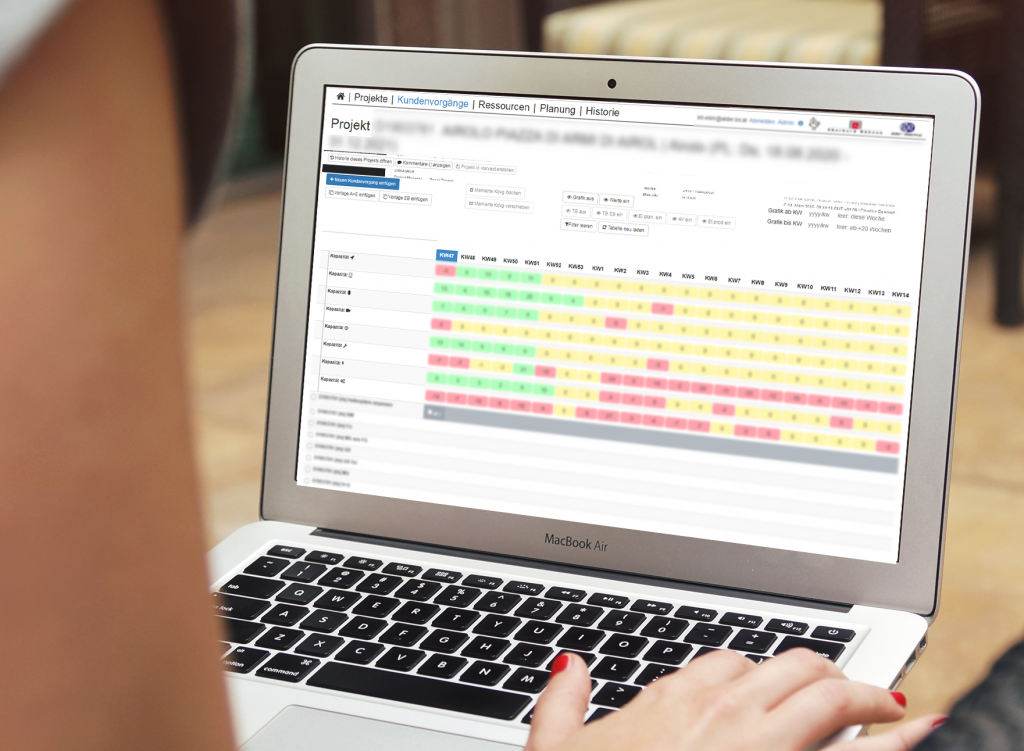

Together with Intelliact, Alder+Eisenhut developed a web-based solution for the entire planning process of the projects managed in the ERP in order to enable parallel work and to make the planning situation and progress status transparent.

Challenge: Access restrictions and synchronisation problems

Alder+Eisenhut is active in sports facility and stage construction. The planning and administration of their orders and capacities was done using an Access database in combination with Excel lists. The disadvantages of this solution are obvious: only one user had access rights at a time. In addition, there were synchronisation problems between the Excel lists, the "central" Access database and the ERP system, which sometimes resulted in redundant entries. Also, the history of the entries could usually not be clearly traced.

Implemented: Web-based solution

Intelliact developed a web-based solution that covers the entire planning process for the projects managed in the ERP. Alder+ Eisenhut is now able to manage the demand planning by means of project positions:

- Project items are assigned to the domains involved (e.g. electrical planning, construction, assembly).

- The resources and capacities (= employees) required for this can already be displayed with the respective availability in relation to the provisional target date windows.

Thanks to the new Digital Service, Alder+Eisenhut can organise the rough planning of resources and capacities more efficiently and assign project domains with a "working week" resolution. The detailed planning of resources and capacities is then carried out per week with the resolution "Comma hours".

Intelliact connected the new solution to the ERP system (planning resources) via REST API. After implementation, it was also possible to add a "mobile hours recording for installation assembly workers" in a further step.

Efficient planning for sustained high customer satisfaction

The new digital service allows multiple access and parallel working without restrictions. Since all the project planning data entered is stringently built on top of each other, no redundant entries are made. The current planning situation and the progress status can be viewed at any time - both by the "planners" and the "consumers" - with the greatest possible transparency. Employees can track all entries and changes in the planning tool in detail in a history log.

Alder+Eisenhut benefits from the digital service in several ways:

- On the one hand, project deadlines can be planned and adhered to more efficiently and reliably. The reduced effort lowers costs. The optimally utilised capacities increase earnings.

- On the other hand, Alder+Eisenhut creates a sustainably high level of customer satisfaction.

Would you also like to access your master and transaction data in the various company applications at any time and from anywhere - with the guarantee that the data used is always up to date? We would be happy to get to know your challenges and support you as a conception and implementation partner in the realisation of your project.