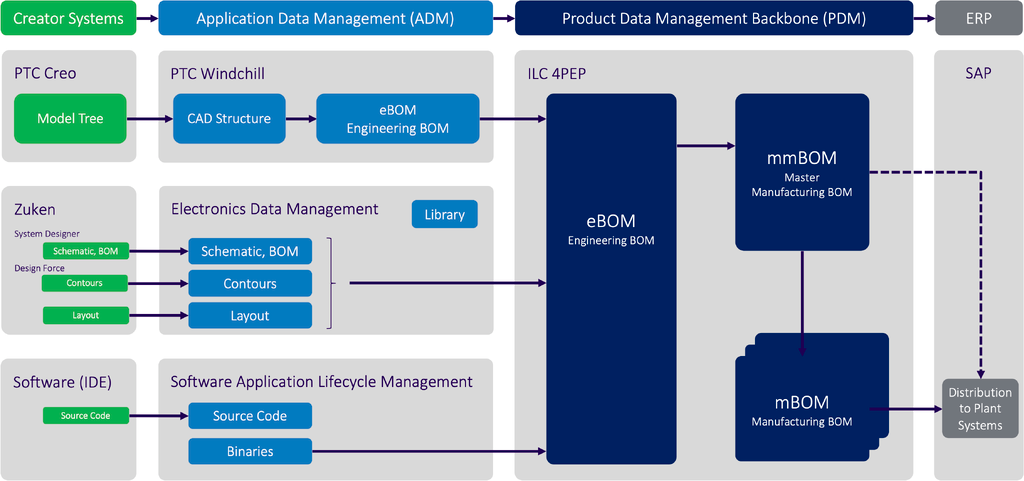

Conception of PLM architecture for End2End integration

How a global PLM architecture enables the end-to-end integration of a business unit in a major global corporation.

Ensure up-to-date product data and consistent product structures throughout the Group

The Group was working with numerous, isolated systems and distributed documents, which required an increasing amount of manual maintenance. A newly designed, forward-looking End2End strategy enabled all product data to be channelled along the information flow and distributed accordingly in the systems. This made it possible to increase the quality of the data ("only enter data once" - data consistency is controlled via the process) and ensure faster availability. At the same time, the Group was able to use this basis to set up other urgently needed function modules such as end-to-end variant management. The most important advantages at a glance:

- 50% faster throughput times for product data from engineering to production

- 20-30% less effort for searching and identifying product data

- 40-50% less effort for compiling documentation for audits

- Clean starting position for the further integration of peripheral systems

- Greater attractiveness for new and existing employees

PROJECT CHALLENGES

Replacing document-based and highly manual working methods

In the past, product development in the Group was primarily handled using Excel lists and various other documents. The high level of data redundancy and different working methods resulted in an increasing amount of manual maintenance work. This was particularly because a greater number of variants led to a massive increase in product complexity. In addition, there was a lack of standardised views of product statuses, especially during changes, which regularly led to considerable additional workloads for all domains involved. These developments were in constant contrast to the shorter time-to-market demanded by management.

IMPLEMENTED BY INTELLIACT

Conception of the PLM architecture as well as analysis, evaluation and introduction of a PDM tool

Intelliact developed and verified the architecture together with the customer and supported the group in designing the optimum PLM architecture as well as orchestrating and integrating the IT tools required for this.

The focus was on the consistency of structures and the creation of a "single source of truth" for all mechatronic disciplines in a PDM backbone. The technical product documentation managed there not only provides an overview but also an ideal starting point for deriving production views for internal and external plants. Particularly in the event of changes, the new consistency across the entire product life cycle creates a high level of transparency regarding product statuses while significantly reducing maintenance efforts.

The implementation of a "proof of concept", in which the central use cases were run through by users in a real system environment, ensured concept security and better integration of subsequent users. Intelliact provided the technical project management and coordinated the activities of the various departments, central IT, and external system providers.

Faster time-to-market, higher data quality and transparency

The primary benefit of the new End2End working method is the support of the development process up to and including the provision of production-ready structures in the plants – for new developments as well as sample and series changes. All process participants now have access to the product data and can enrich it in the respective structure. The integrated working method has shortened the time-to-market and increased end-to-end consistency from development to production. In addition, the newly created "single source of truth" now gives all employees access to both current and older product versions – for transparency and traceability at all times.

Do you also need support with the neutral categorisation and optimal orchestration of your system landscape? We would be happy to get to know your challenges and support you as a competent partner in the design and implementation.