Interactive 3D visualization for fast, intuitive selection of powder coatings

How the global powder coating manufacturer IGP evolved its previously analogue sampling and ordering process into a modern B2B platform with online sampling for more than 1,000 powder coatings.

- Swiss family-owned company founded in 1968

- Leading powder coating manufacturer (15,000 tonnes of powder coatings per year)

- Production sites in Switzerland, Poland and the USA

- With 21 subsidiaries and distribution partners worldwide

- More than 500 employees

What it’s about

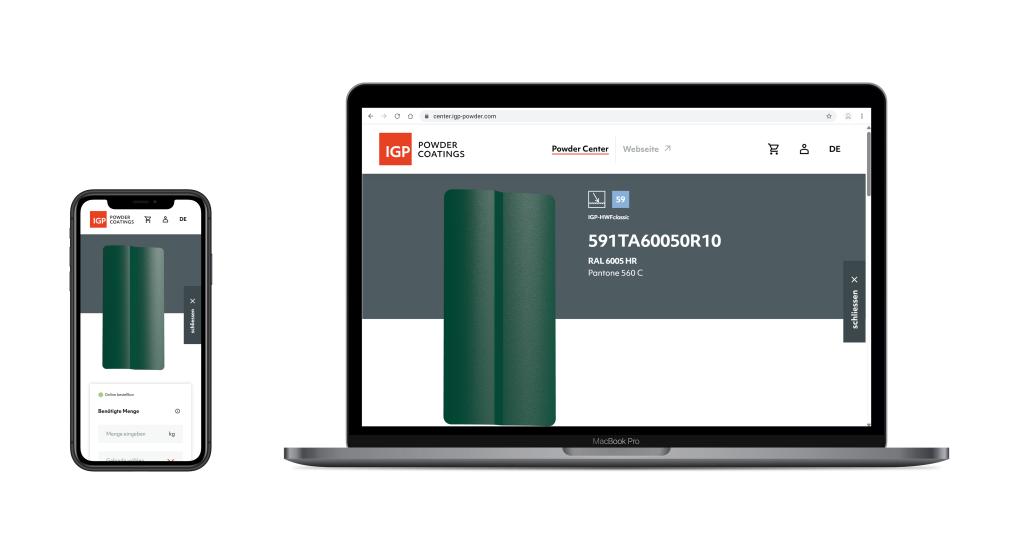

Modern e-commerce platform with 3D visualization

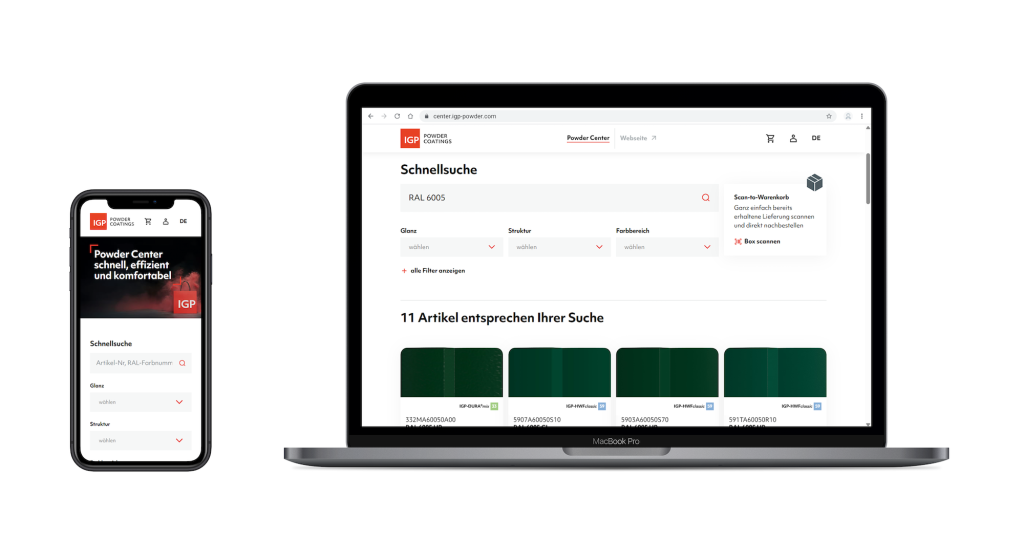

The objective was to digitalize IGP’s previously analogue sampling and operational process. To achieve this, Intelliact, together with IGP, designed a new digital product platform: the Powder Center. It combines the functionality of a modern B2B e-commerce application with a digital sampling process. The interactive 3D visualization makes surface structures, gloss levels and reflections of powder coatings visible under different lighting conditions. This enables customers to assess colors and coatings more easily and efficiently.

Project challenges

Structured, seamlessly connected data from development to sales

To guide B2B customers to the right product as efficiently as possible, consistent data flow from development through production to sales is essential. Particularly noteworthy is the connection with business applications such as ERP, for example for customer-specific pricing, and PIM, for example for complete downloads. All product data must be recorded and maintained exclusively in the system of the respective domain, whereby redundancies are consistently avoided. For seamless connectivity, physical measurement data for gloss, color tone and similar properties, as well as master data such as curing conditions or approval requirements, must already be captured and structured during development. On this basis, digital twins are created and are immediately available for virtual sampling in the e-shop. In parallel, the necessary processes and interfaces had to be established in sales to enable fully digital transaction handling.

Implemented by Intelliact

High-performance application – custom-built

Together with IGP, Intelliact defined a system-neutral concept and selected a custom software solution designed to meet the specific requirements over the long term. In collaboration with the design agency Eyekon, a modern visual design with clear user guidance was created. Aligned with IGP IT’s security and cloud requirements, Intelliact developed the system architecture as well as the complete application.

Benefits for IGP Pulvertechnik AG and its customers

Reducing costs, saving time

The new Powder Center also accelerates the sampling process, as the entire selection workflow takes place online – from an initial broad selection with dozens of items to the final two or three suitable variants. In addition, customers can place orders with minimal effort thanks to the digitalization of inside sales, including features such as barcode scanning. The result is reduced costs for producing and shipping physical samples for IGP, while customers find the right coating product faster and more easily. In future, for example, it will be possible to order sample sheets or send digital sample collections consisting of 3D images (digital twins) directly to architects. In addition, the interactive 3D views can be offered as a white label solution for integration by customers. Following a successful launch and consistently positive feedback, the outlook is strong for a rollout in all key IGP markets in the near future.

Are you also looking for a partner to design and implement innovative digital solutions? As an experienced partner, we are happy to support you and develop solutions that integrate seamlessly into your existing enterprise systems.